elevator machine room requirements nec

Be run through the elevator machine room. Selective coordina-tion is also required for multiple elevators per NEC 62062.

General Installation Requirements Part Xx Electrical Contractor Magazine

ASME Code requires that the temperature within an elevator equipment room be maintained between 55 and 110 degrees F non-condensing.

. HVAC Equipment MUST NOT be mounted above ANY elevator equipment. Standard machine room layout for a residential hydraulic elevator. Another important electrical system design.

A Have a minimum width of 30 in. 762mm for other spaces specified in Sections 3011e2 and 3011e3. Access doors shall be provided for all elevator machine rooms or enclosures and shall conform to the following.

In all cases the working space must permit at least a 90 opening of. Control room must be of adequate size to provide clearances around and between equipment as required by code. Space is provided for a wheelchair user to enter reach controls and exit the elevator car ADA 4108 Door opening is at least 36.

The basic requirement is for minimum clear distances of various depths for equipment operating at 600 V or less nominal depending upon voltage to ground and lateral distance to insulated or grounded surfaces or exposed live parts not an issue in elevator machine rooms. Per the 2017 NEC if the elevator is designated as an emergency system load the disconnect must be protected by a surge protective device SPD. The temperature and humidity range shall be permanently posted in the machine room.

Cab length is at least 51 with at least 54 from the back of the cab to the face of the door. In some cases it may require a means to test the shunt trip operation or have one contact operate the shunt trip of more than one elevator. The NEC doesnt define a dedicated circuit hoever the section calls for a separate branch circuit for machine room lighting and receptacles.

The dimensions allow for a safe working clearance around the electrical equipment required by the national electrical code or NEC. For hoistway pit and machine-room lighting must be located How unsupported lengths of traveling cables are measured In Part One of this series ELEVATOR WORLD April 2012 we began an examination of National Electrical Code NEC 2011 mandates for eleva-tors and related equipment installa-tions. This is typically accomplished by a shunt-trip device.

This clear working space must be 30 in. We resume with a look at wiring. C12 ELEVATOR MACHINE ROOM REQUIREMENTS 1.

Elevator machine room lighting. The elevator machine and controller must be located in the elevator machine room. An elevator machine room must be provided for each individual elevator or elevator group.

The minimum recommended size is 5-5 deep and 4-6 wide shown in this plan. The main level of the machine room is far too tight to accommodate the new distribution board and therefore in order to satisfy the line of sight requirements under section 62051 of 2008 NEC with NYC Amendments we plan to install a second fused disconnect switch near the elevator drive for each individual elevator on the secondary side of the new. ANSIASME A171 28332 Safety Code for Elevators and Escalators and the NEC 62051B require power to an elevator be shut down prior to the release of water in the elevator shaft or machine room.

All of these options and special wiring can be challenging depending upon the. Cab width for side opening doors is at least 68. Check the NFPA 101 Life Safety Code for emergency lighting requirements.

Where machine rooms are provided the disconnecting means required by 62051 shall be located within 610 mm 24 inches of the open side of the machine room access door. Given that elevator equipment produces a substantial amount of heat space cooling is typically required. Rule 1021 Installation of Electrical Equipment and Wiring in Hoistways and Machine Rooms.

If elevators are supplied by the emergency legally required standby or critical operation power systems then selective coordination is required per the 2017 NEC in 70032 70127 or 70854. Wide or the width of the equipment whichever is greater. See section 62023 of the NEC.

Shunt-trip voltage monitoring and control circuit tied into Fire Alarm System. Electrical Component NEC Clearances. Live parts not an issue in elevator machine rooms.

Wiring installed for the purposes indicated in this rule are only to enter hoistways machine rooms and machinery spaces to the extent necessary to provide for proper installation of the device attached thereto. For facilities not located in a flood zone locate hydraulic elevator machine rooms on the lowest landing served by the elevator. Elevator equipment manufacturer to ensure safe and normal operation of the elevator.

The electricians work and equipment placement shall be coordinated with the elevator contractors equipment placement. BEFORE constructing a machine room space the dimensions should be verified with current. Provide a legally constructed and enclosed control room adequately lighted and conditioned to maintain temperature between 32 to 104 Fahrenheit relative humidity is not to exceed 95 non-condensing.

Where more than one disconnect is required for a multi-car group the disconnects shall be adjacent to each other with the first disconnect located within 610 mm 24 inches of the open side of the machine. Space heating is rarely required and thus has not been addressed here. Shaft and Mechanical Room Limited equipment above car Pistons in shaft Hydraulic machine room Controller and reservoir Limited Travel Machine Room Traction Elevator Strictly mechanical Direct drive or pulley drive from adjacent room With counterweight.

762mm and a minimum height of 6 ft 183m for machine rooms and a minimum height of 30 in. It need not be exactly centered on the equipment and working spaces of adja-cent pieces of equipment may overlap. Clearances around all electrical equipment in the elevator machine room shall comply with NEC 110-26 electrical clearances requirements.

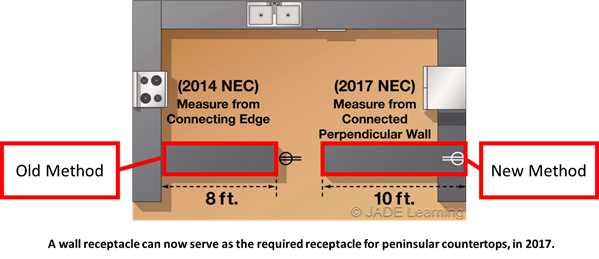

Nec 210 52 C 3 New Peninsular Receptacle Requirements For The 2017 Nec Jade Learning

Inspecting Elevator Power Wiring Iaei Magazine

Nec Requirements For Ground Fault Circuit Interrupters Gfci Ec M

Emergency Systems And The Nec Ec M

Nec Requirements For Emergency Systems Eep Emergency System Nec

5 Key Considerations For Single Family Residential Electrical Services Based On The 2020 Nec Nfpa Nfpa

Nec Article 620 11 50 15 54 Asme A17 Series Of Elevators Escalator Standards

General Installation Requirements Part Xx Electrical Contractor Magazine

Legally Required And Optional Standby Systems Ec M

Compliance With The 2017 Nec For Elevator Controllers Iaei Magazine

Caution Area In Front Of This Electrical Panel Must Be Kept Clear For 36 Inches Sign Reflective Electrical Panel Room Signs Room Signage

Nec Article 620 Elevators Part I

5 Key Considerations For Single Family Residential Electrical Services Based On The 2020 Nec Nfpa Nfpa

Nec Article 620 Elevators Part 1

Compliance With The 2017 Nec For Elevator Controllers Iaei Magazine

Oesc 620 51 Disconnecting Means

Nec Article 620 11 50 15 54 Asme A17 Series Of Elevators Escalator Standards

Compliance With The 2017 Nec For Elevator Controllers Iaei Magazine

Sprinkler System Design For Fire Fightings Fire Sprinkler System Sprinkler System Design Fire Protection System